- work as flow

- workflow as knowledge discovery steps

- knowledge work as a service

- organizations as networks of services

|

| Video of the "Kanban Lens" lightning talk (7 minutes) |

But that still didn’t explain what the Kanban method was.

A few years ago Rodrigo Yoshima used an eye-opening phrase in a talk he did at Lean Kanban North America: the “Lean flow paradigm”. It helped me understand that Kanban is not a process, or a recipe, or a framework. It’s how to see work. This is what brings together the many and various parts that make up the Kanban method. In 2013, David Anderson blogged about this, coining the phrase “the Kanban Lens” and recently I’ve been talking to David again about its definition, looking for a simple form of words that captures the Kanban “way of seeing”.

There are four elements to the Kanban Lens.

1. See work as flow

Firstly… “See work as flow.” Or more explicitly: See work as a flow “from customer need, to needs met.” This is the starting point for using Kanban. Before you change the organisation, or the process, or the roles and responsibilities, or anyone’s job title, change how you view your work. Seeing work as flow may seem obvious. Except that this is completely against most managers' and most professionals' instincts. It's not how work is traditionally managed. When you look at what people actually do, it's clear; most of us are more concerned about people who are not busy, than work items that are not flowing!

Change your viewpoint. Don’t view your work as being busy at your skill, or your role. Work has value because, we fulfil customers’ needs. By visualising work and ensuring it's made up of small, distinct items, the flow of work becomes visible. Ensuring each work item is coherent and valued by the customer, means genuine value can be delivered to the customer as each item is delivered.

That’s how work flows. Workflows... that's the second element of the lens...

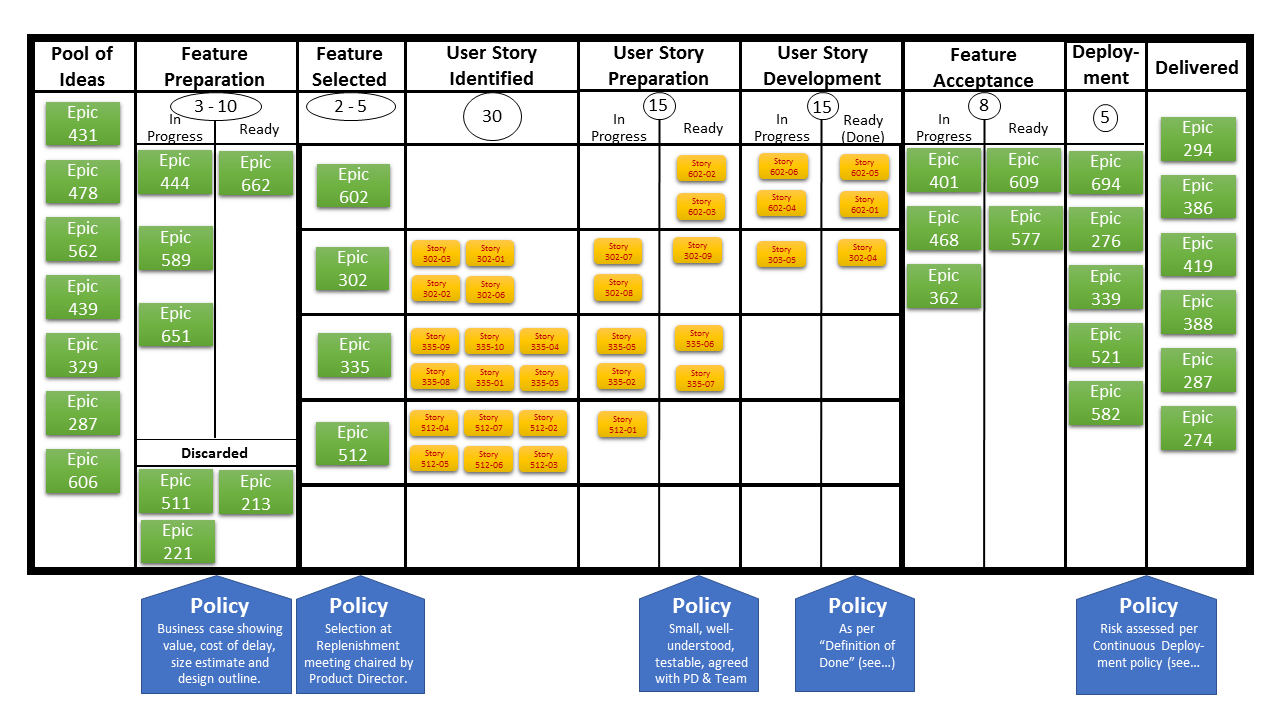

2. See workflow as a sequence of knowledge discovery steps

Workflow as a sequence of knowledge discovery steps is something that often puzzles people. It cuts across how we've traditionally looked at workflow - as hand-offs between individuals or teams. However the columns on a kanban board should not be viewed as representing the teams of people that handle the work. Look through a different lens. The workflow shows the progress of the work item, through different learning activities, until we know enough about each item, to convert the ideas and options into delivered value.

“Really? How can we expect a linear monotonic process to represent such complex activities?”

The answer is that we don’t, and it doesn’t. The steps in a Kanban process are states of the item. In each state there’s a dominant means of learning (of knowledge discovery), using people and skills as needed. This is how to build effective, improvable services.

3. See knowledge work as a service

The third element of the Kanban lens is to “See knowledge work as a service.”

Again this raises eyebrows. “Isn’t it obvious that knowledge work is a service? Accountants and tax men call it a service. The product is intangible. There is no manufacturing involved.” But that’s not the source of the controversy. Our instinct is to manage what’s visible – the people; rather than what’s invisible – the work being produced. The Kanban Lens asks us to focus on the work, not the workers, and to see that work as a service.

A service implies the existence of a customer, needing, and ultimately benefiting from, the work.

It implies care on the part of the service provider…

- to know what makes the service fit for the customer’s purpose, and

- to what degree, and when, it can be delivered.

4, See your organisation as a network of services

Multiple inter-dependent services require organising, and that's where the fourth element of the lens comes in. “See your organisation as a network of services.”

Network here is a general term. Typically we see

- chains of services

- hierarchies of services, and

- inter-connected services

[CC BY-SA 4.0 (https://creativecommons.org/licenses/by-sa/4.0)], via Wikimedia Commons]

These networks must be balanced by adjusting the policies and resources to ensure flow and timely delivery. Management cadences for improvement are therefore vital, particularly an Operations Review, which interacts with multiple services.

Scaling Kanban depends on this first step of seeing the organisation differently… as a network of services. The "org. chart" is no help for this. But when people see the services, and their customers, they can

- self-organise to the work

- cut the waste of siloed thinking and redundant activities, and

- generate improvements from within… across the organisation.

- See work as flow (from customer need, to needs met),

- See workflow as a sequence of knowledge discovery steps

- See knowledge work as a service

- See your organisation as a network of services

References and Credits

Anderson, David J. 2011 “Understanding

the Process of Knowledge Discovery”. DJAA blog: http://www.djaa.

com/understanding-process-knowledge-discovery

Anderson, David J., and Andy Carmichael.

2016. Essential

Kanban Condensed.

Lean Kanban University Press. http://leankanban.com/guide

Carmichael, Andy. 2013. “How to Adopt

Kanban”, Improving

Projects. http://xprocess.blogspot.co.uk/

2013/05/how-to-adopt-kanban.html

Carmichael, Andy. 2017. "Sample

Kanban Board“, CC BY-SA 4.0 via Wikimedia Commons. https://commons.wikimedia.org/

wiki/File%3ASample_Kanban_Board.png

Ebbesen, Bill. “Lenses” Photo. Transferred from en.wikipedia, CC BY 3.0, https://commons.wikimedia.org/

w/index.php?curid=11430342

“Kanban (development)”. Wikipedia. Retrieved July 7, 2017, https://en.wikipedia.org/wiki/Kanban_(develop

ment)

Kennedy, Michael. 2012. “Set-Based

Decision Making”, Lean

Software and Systems Conference,

Boston, MA. Video: https://vimeo.com/42785298

USDA, “Large format camera”

Photo. PD-USGov-USDA-ARS. https://commons.wikimedia.org/wiki/File%3A

Large_format_camera_lens.jpg

Yoshima, Rodrigo. 2013. "Management and Change - Avoiding the Rocks," Lean Kanban North America, https://www.slideshare.net/rodrigoy/management-and-change-avoidin.

Zheglov, Alexei. 2014. “Beyond VSM: Understanding and mapping your process of knowledge discovery”, Lean Kanban Central Europe. Slides: https://goo.gl/ay6P7U, Video: https://vimeo.com/ 114542264

Yoshima, Rodrigo. 2013. "Management and Change - Avoiding the Rocks," Lean Kanban North America, https://www.slideshare.net/rodrigoy/management-and-change-avoidin.

Zheglov, Alexei. 2014. “Beyond VSM: Understanding and mapping your process of knowledge discovery”, Lean Kanban Central Europe. Slides: https://goo.gl/ay6P7U, Video: https://vimeo.com/ 114542264

No comments:

Post a Comment